chocolate production line consisting of 7 pieces

Negotiable|1 piece/pieces(MOQ)

| Quantity (piece) | 1 - 100 | > 100 |

| Lead time (days) | 10 | To be negotiated |

Sold By: Elit machine

- metal

Product Description

Tempering system chocolate rate

It is completely made of AISI304 stainless steel. .Control by PLC and HMI.. PID controlled dry heating.. Chillers and water pump.. Automatic adjustment of cold water temperature.. Tempering capacity 75 kg/h.. Loading capacity 50 liters. Total power consumption 220V 2.5kW

One Shot Chocolate Pourer is made entirely of AISI304 stainless steel, aluminum and engineering plastic. Mixer with pneumatic motor. Vertical movement with servo motor. The dry heating is PID controlled at 24V. Servo motor suction and discharge. Tanks with level sensors. Common valve mechanism of pistons. Safe against cold work. the above. Possibility of printing the product 1000 grams/stroke. Maximum production capacity. 20 beats/min. Total power consumption 380V 5kW

Fully stainless chocolate fanner AISI304. AISI420 mixer shaft is stainless. The mixer arms are made of a special solid material. Waterwall boiler. PID controlled heating. Possibility of adjusting grinding time. Safe against cold work. Solenoid valve allows cold water to pass through in case of overheating. Loading capacity 750 litres. (1000 kg.) Total power consumption 380V 30.5 kW. Cold water must be provided from the external environment

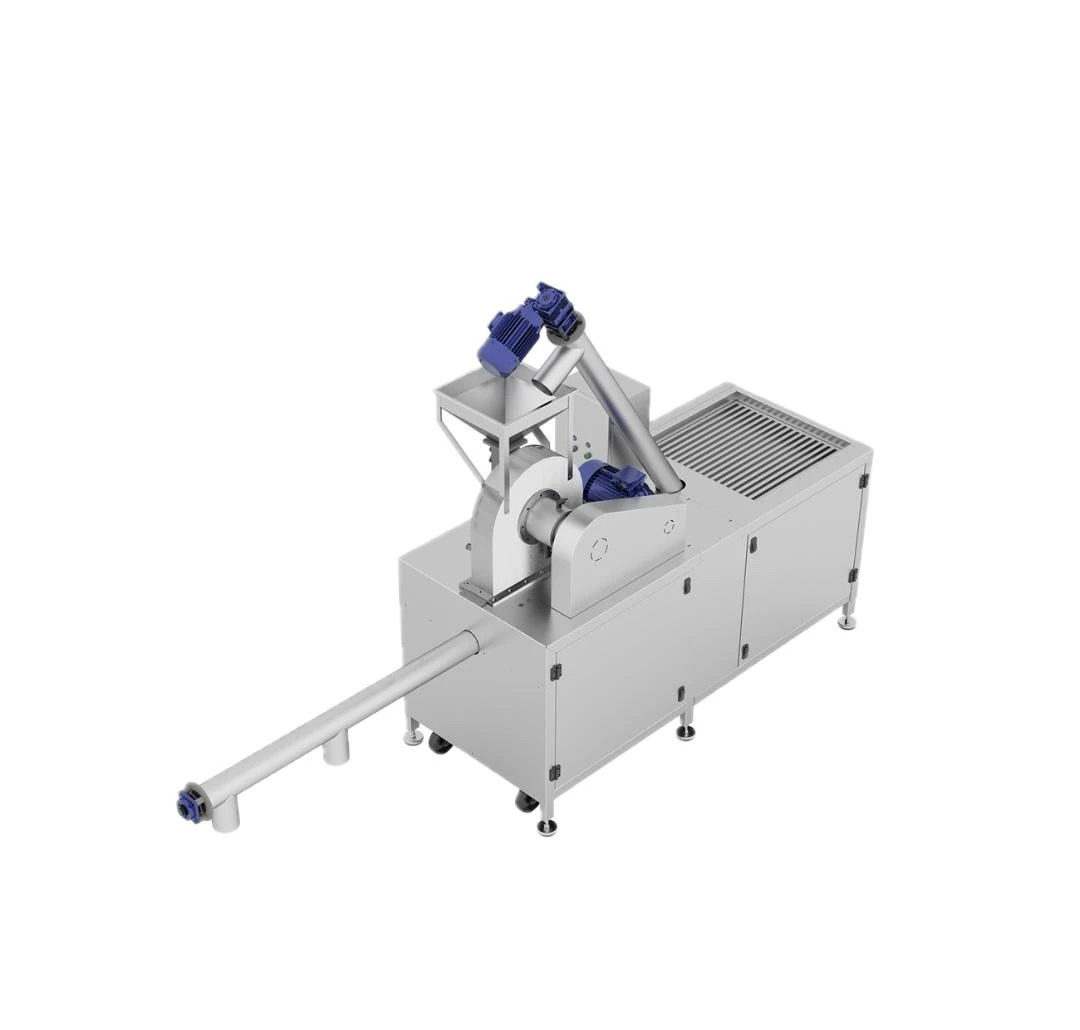

Sugar or salt mill made entirely of stainless steel AISI304. 200 kg/h. Hammer type rotor assembly reaches capacity. 100kg/h pin type rotor and stator assembly reach capacity. Sugar grinding pins are made of 16MnCr5 material. Dust collection filter. AISI304 screw type stainless product receiving conveyor. Air regulating and shut-off valve to control product flow. At higher capacities, the main bearing assembly is water-cooled. Rotating top node network. Magnetic filter. ~50-80 µm. Production capacity is 200 kg/hour. Total power consumption 380V 5kW

Two-color chocolate filling machine. Made entirely of AISI304 stainless steel, aluminum and engineering plastics. With two rooms. Product level sensors in hoppers. Vertical movement with servo motor. Servo motor nozzle twisting feature. Safe against cold work. Hot and stirred room. It is easy to adjust the volume by pressing. Modular jar transport conveyor. Jar feeding tray. Production capacity is 7 containers/minute. Jar receiving tray

Packages per hour for 1 liter packages 700 Packages per hour for 1 liter packages 1400 Packages per hour for 1 liter packages 2100 Packages per hour for 1 liter packages 2800 Packages per hour for 1 liter packages 3500 Packages per hour for 1 liter packages 4200

Fener chocolate. 304 It is made of AISI 304 stainless material. Double jacket water heating. Capacity 500kg/3h. A special steel ball bearing weighing 500 kg was used. Specially angled stabilizers allow the balls to move up and down, thus thinning the chocolate mixture.

Send your message to this supplier

For better quotations, include:

- A self introduction

- Special requests, if any