arabic oven

$ 94999.9 ~ 95000/ piece|1 piece/pieces(MOQ)

| Quantity (piece) | 1 - 100 | > 100 |

| Lead time (days) | 10 | To be negotiated |

Sold By: saryamakine

- metal

- metals

Product Description

Result BreadArab/Syrian/Lebanese BreadCapacity2500 Pieces / HourTotal Electric Power12 KwTotal Number of Integrated Machines6Total Air Requirement6 barsWorking Method1 RowStandartsISO 9001-2015 and CE (Conformité Européenne)

Category: Arabic Pita Bread Line

Tags: arabic bread line, arabic bread machine, lavash bread line, lavash machine, lebanon bread line, lebanon bread machine, syrian bread line, syrian pita bread line

The working principle and operation of this production line is as follows:

Dough Preparation:

At this stage, flour, water, yeast, salt and other ingredients suitable for lavash and pita bread are mixed. This mixture is kneaded to obtain dough. And the kneaded dough is covered and the first fermentation process is achieved.

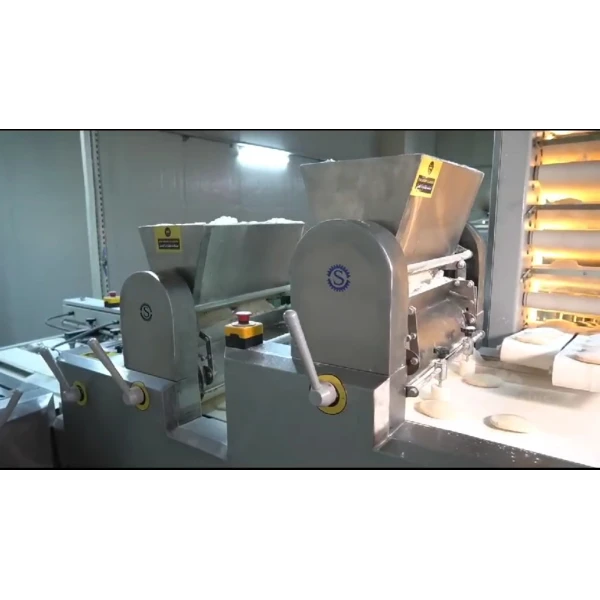

Dough Cutting and Shaping:

To obtain a certain shape and size, the kneaded dough is cut in the desired weight on the cutting machine and opened in the desired dimensions on the rolling machine.

Fermentation:

Shaped dough balls and rolled dough are left to ferment for a certain period of time. This process is important for fermentation and volume gain of the dough.

Baking:

Following fermentation, the dough is usually baked in ovens at high temperatures. This allows the dough to rise and take on a bread consistency.

Cooling and Packaging:

The baked bread is cooled and then packaged. This stage ensures that the product is ready for storage and distribution.

Each bread production line design can vary depending on a particular producer’s needs, production volume and the types of products it will produce.

Send your message to this supplier

For better quotations, include:

- A self introduction

- Special requests, if any