spark 120 packaging machine

$ 1 ~ 0/ unit|2 unit/units(MOQ)

| Quantity (unit) | 1 - 1 | > 1 |

| Lead time (days) | 60 | To be negotiated |

Sold By: ZIRVE INTERNATIONAL MAKINA

- metals

Categories:machinerypackaging machinesfilling machines

Product Description

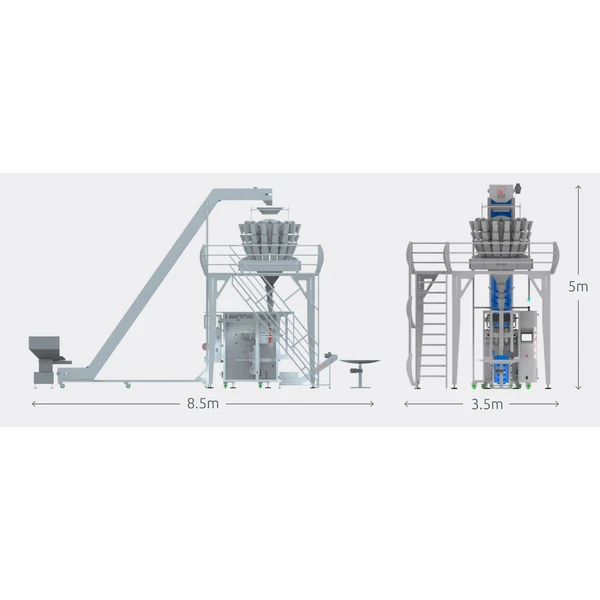

SPARK 120 . Precision Weighing System Filling and Packaging Line

The latest technology of precision-moving servo motor drive and control systems has been used and programmed with the help of experts from Germany

To give great performance, super speed and continuity in continuous work 24/7

Equipped to fill all kinds of chips, snacks, nuts, legumes, pasta

(FILLING GROUP) :

• weighing tower equipped with 20 modern and advanced scales (smart collection

system ) from the international company HIGH DREAM

• the filling device of this machine is entirely made of (STAINLESS STEEL 304)

• the weighing platform has been designed in a strong and durable style taking into account

the elegant exterior to suit the machine model and the 20 bucket scale

• two control screens which is the scale is divided into two parts that work alternately to suit high speed

• the weight system works from 10 gr to 1 kg taking into account the volumetric mass of the

• materials single bucket capacity is 1.6 litres

• the controls system is done by a 10 inch color touch screen that contains 3 languages

• equipped to save 99 different programs

• simple and easy to calibrate programming system

• equipped with automatic or manual ressetting system

• the possibility of controlling the speed of opening and closing the buckets according to the nature of the product

• equipped with a comprehensive test system for all movements of the scale

• the filling tank equipped with a (photocell) feeding system from (SICK – GERMANY) to control the feeding line

• equipped with a central circular feeder

• equipped with 20 precise and calibrated horizontal vibrators

• equipped with 20 easy to release and easy to install wait buckets

• equipped with 20 easy to release and easy to install weight buckets

• spare parts included with the scale (weight sensor- gate drive sensors- waterproof gaskets)

(PACKAGING GROUP) :

• the machine is entirely made of (STAINLESS STEEL 304 )

• the machine works with a pneumatic system (advanced German technology, welding movements are done by compressed air)

• the mechanical motors for the moving part of the machine are made of European aluminum due to its light weight

• the pack shape is a welded pillow from three sides

• production capacity 90/120 pack per minute (according to the packing weight -the nature of the packed material-the quality of packing paper

• the machine is equipped with 2 of the best Italian packing molds

• the allowed width of the pack is from 7 cm to 20 cm

• the allowed lenght of the pack is from 10 cm to 36 cm

very easy to release and install roll system (pneumatic system)

• patented continuous vertical welding system easy to adjust and calibrate and adapts with continuous pulling and high speeds

• distinguished roll feeding device compressed air technology was used to adjust the calibrated continuous roll feeding mechanism

• the moving part is a servo motor with a driver with a strong and durable gearbox from the best german companies

• the horizintol welding servo motor with a driver with a strong and durable gearbox from the best german companies

• the mechanism for pulling the roll and adjusting the length of the pack is done by a servo motor with a driver with a strong and durable gear box from the best german companies

• with control encoder for roll pulling and the performance of the pulling belt

• equipped with an italian vacuum pump equipped for continuous work 24/7

• equipped with roll displacement control sensors from the best german companies

• equipped with a fast photocell reading sensors to read the black dot and determine the length of the pack

• the pulling system is done by high quality belts specially designed to match the high speeds

• pistons .control valves.pressure measuring unit.oiling unit.monitoring

unit.connecting hoses all are from (SMC JAPAN) company

• a carefully and specially designed horizinto welding system suitable for high speeds

• patented instant cooling system after welding equipped with a 12 inch high definition color control screen with 4 languages on demand

• the software of the machine was designed and programmed in coorperation with the strongest korean companies

• a smart machine that detects faults and finds immediate solutions

• equipped with electrical protection systems .circuit breakes .and control switches from (SHNIDER-FRANCE) company

• the electricity 380V /10KW/ 50/60 HZ

• equipped with an invertor device from (LS-KOREA) company to control the speed and the engine

• contains 3 servo motors with a control driver from (LS-KOREA) company

• the machine is equipped with a front conveyor to receive ready packs made of (STAINLESS STEEL 304)

• the machine is equipped with an automatic circular table made of (STAINLESS STEEL 304)

• the machine is equipped with buttons and emergency switches that comply with the European CE protection standards

• the machine is equipped with a fiber-class cover for protection and safety. comply to the European CE protection standards

• the machine is equipped with a spare parts box that contains (a set of heaters .thermostats.1 cutting knife .+ 1 set of pulling belts

• the machine is equipped with the latest protection systems from the dangers of voltage fluctuation

• the machine is CE certified

Send your message to this supplier

For better quotations, include:

- A self introduction

- Special requests, if any